Full Safety Assurance, the "Protective Shield" for the Special Environment of Gas Stations

Gas stations are high-risk venues with special and complex operating environments, where flammable and explosive oil and gas vapors, persistent humidity, and potential chemical corrosion coexist. Manhole covers, as important accessories that seal underground pipelines, trenches, and equipment wells, play a crucial role in ensuring the overall safety of gas stations. The safety performance of manhole covers directly relates to the normal operation of gas stations, the safety of employees and customers, and even the surrounding environment. Among various manhole covers available in the market, D400 SMC manhole covers stand out as the ideal choice for gas stations, especially as a high-quality watertight manhole cover, they integrate multiple safety advantages to form a reliable protective barrier for gas stations.

First and foremost, insulation and non-conductivity are core safety features of SMC manhole covers that are indispensable for gas stations. Gas stations are equipped with a large number of power supply lines, control systems, and electrical equipment to support daily operations such as refueling, storage, and monitoring. Once a cable fault or short circuit occurs, conductive manhole covers may generate step voltage, posing a fatal threat to operation and maintenance personnel who walk or work nearby. In sharp contrast to traditional ductile iron manhole covers, which are inherently conductive, SMC manhole covers are made of a composite material composed of glass fiber and unsaturated resin, which is naturally insulated and non-conductive. This inherent property eliminates the risk of step voltage from the source, ensuring the personal safety of staff during daily inspections, maintenance, and emergency handling.

To further adapt to the flammable and explosive environment of gas stations, SMC manhole covers can also be customized with anti-static and flame-retardant properties. The oil and gas vapors in gas stations are highly flammable, and even a small static spark may trigger an explosion or fire. The customized anti-static SMC manhole covers can effectively dissipate static electricity accumulated on the surface, preventing static sparks from being generated. At the same time, the flame-retardant performance of SMC manhole covers ensures that they will not burn or support combustion when exposed to open flames or high temperatures, and their oxygen index meets the strict safety standards of gas stations, further reducing the risk of fire spread. This level of safety customization is difficult to achieve with traditional manhole covers, as cast iron manhole covers have no anti-static or flame-retardant capabilities at all, and additional modification measures are not only costly but also unstable in performance.

Corrosion resistance is another key advantage of SMC manhole covers that makes them highly suitable for gas stations. The environment of gas stations is filled with oil and gas, which are corrosive to most materials, and the soil around manhole covers is often humid, which can accelerate the corrosion of metal materials. Traditional ductile iron manhole covers are particularly vulnerable to such corrosion – over time, the surface anti-corrosion layer will peel off, and the cast iron itself will rust and corrode. As corrosion progresses, the structure of the cast iron manhole covers will be damaged, leading to thinning, deformation, and even rust-through, which not only affects the load-bearing capacity of the manhole covers but also may cause the covers to collapse, leaving serious safety hazards for gas stations. In addition, the rust generated by cast iron manhole covers may contaminate the soil and underground water sources around gas stations, causing environmental pollution.

In contrast, SMC manhole covers exhibit excellent resistance to oil-gas corrosion, acid and alkali corrosion, and humid environment corrosion. The composite material structure of SMC is stable and does not react with oil, gas, or chemical substances, ensuring that the manhole covers will not rust, peel, or deform even after long-term exposure to the harsh environment of gas stations. This corrosion resistance not only extends the service life of SMC manhole covers but also maintains their structural integrity and safety performance for a long time, reducing the frequency of replacement and maintenance. For gas stations, which pursue long-term stable operation, the corrosion resistance of SMC manhole covers can significantly reduce hidden safety risks and operational costs.

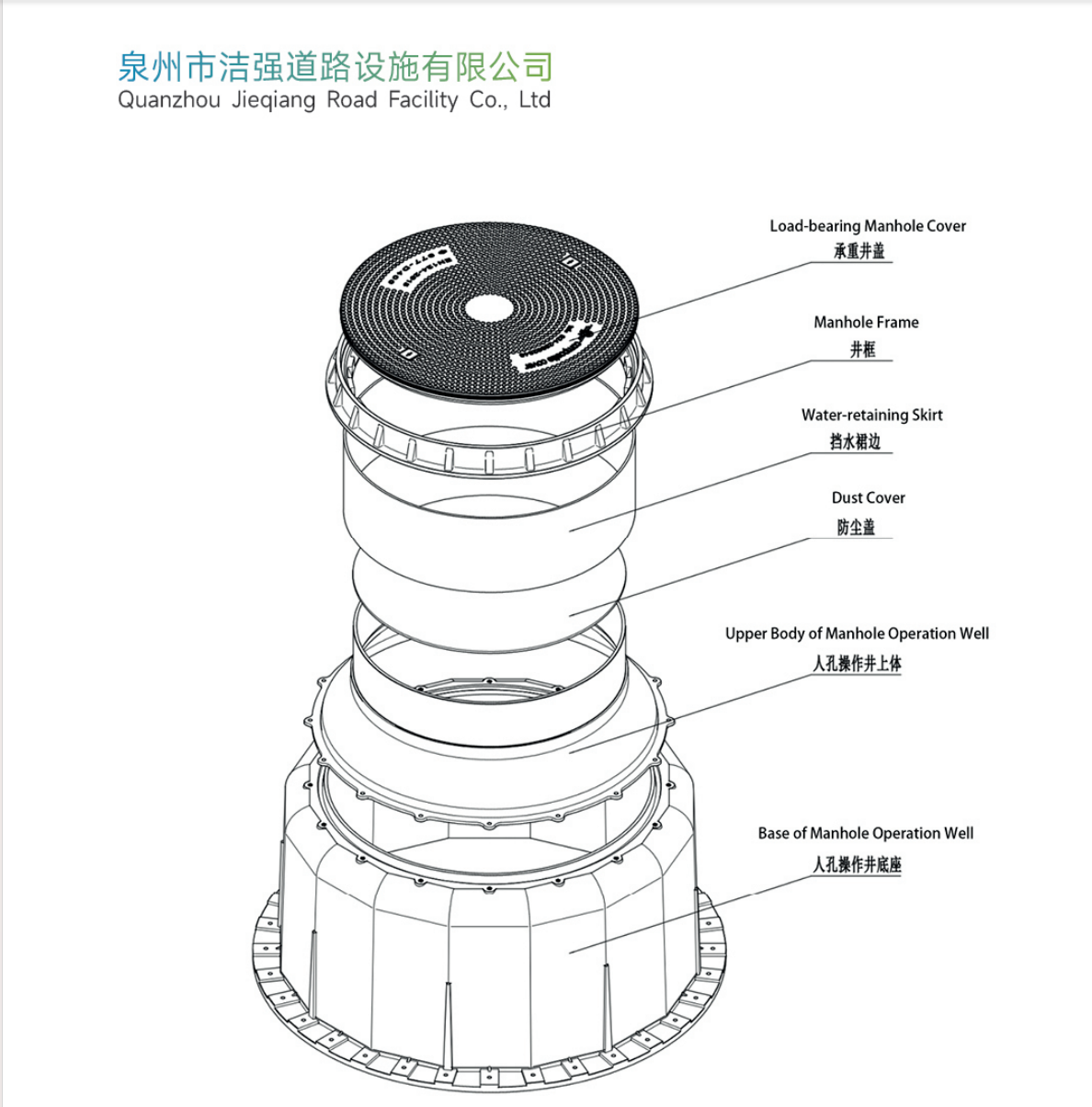

As a professional watertight manhole cover, the sealing performance of SMC manhole covers is also fully optimized for gas stations. Humidity is a common problem in gas station trenches and underground wells, and water accumulation can easily cause short circuits of electrical equipment, corrosion of pipelines, and damage to mechanical components, affecting the normal operation of gas stations. SMC manhole covers are equipped with high-quality rubber sealing rings around the edges, and the cover and the well seat are designed with a tight fit structure, which can effectively prevent rainwater, groundwater, and oil stains from seeping into the well. The watertight performance of SMC manhole covers is far superior to that of traditional manhole covers – cast iron manhole covers have poor sealing due to structural limitations, and concrete manhole covers are prone to cracks, leading to water seepage. By maintaining a dry environment in the well, SMC manhole covers effectively protect underground equipment and pipelines, reducing the probability of equipment failure and maintenance costs.

It is worth noting that the safety advantages of SMC manhole covers are not only reflected in their own performance but also in their compatibility with the overall safety management of gas stations. For example, SMC manhole covers can be customized with obvious warning signs and safety labels, which are wear-resistant and non-fading, helping staff quickly identify the purpose of the well and potential risks. In addition, SMC manhole covers have no recycling value, which inherently prevents theft – stolen manhole covers can lead to open wells, posing a great safety risk to pedestrians and vehicles at gas stations. Traditional cast iron manhole covers, due to their high recycling value, are frequently stolen, forcing gas stations to install additional anti-theft locks or take other security measures, which increases operational costs and management troubles.

To further illustrate the safety advantages of SMC manhole covers in gas stations, we can compare them with traditional ductile iron manhole covers in practical application scenarios. Suppose a gas station uses cast iron manhole covers in the refueling area – after one year of use, the surface of the cast iron manhole covers begins to rust, and the conductive risk increases; after three years, the corrosion becomes severe, and the anti-corrosion layer peels off, requiring regular derusting and repainting. In addition, due to poor sealing, rainwater seeps into the well, causing corrosion of the internal cables and increasing the risk of short circuits. If the same gas station uses SMC manhole covers, after five years of use, the manhole covers still maintain a clean surface without rust or corrosion, the insulation and watertight performance remain stable, and no additional maintenance is required. This comparison clearly shows that SMC manhole covers can provide more reliable safety protection for gas stations.

In addition to the above advantages, SMC manhole covers also have the characteristics of lightweight and easy installation, which indirectly improves the safety of gas station operations. Traditional cast iron manhole covers are heavy, requiring multiple people to carry and install, and hoisting equipment is often needed during maintenance, which increases the risk of operational accidents. SMC manhole covers weigh only about one-third of cast iron manhole covers, and a single person can easily carry and install them, reducing the difficulty and risk of operation. For gas stations that need to carry out frequent inspections and maintenance, the lightweight feature of SMC manhole covers can improve work efficiency and ensure the safety of operation and maintenance personnel.

In summary, SMC manhole covers are perfectly adapted to the special safety requirements of gas stations through their excellent insulation, anti-static, flame-retardant, corrosion-resistant, and watertight performance. Compared with traditional manhole covers, SMC manhole covers not only provide more comprehensive and reliable safety protection but also reduce operational costs and management troubles for gas stations. With the continuous improvement of safety management standards for gas stations, SMC manhole covers have become the preferred choice for gas stations to replace traditional manhole covers, contributing to the safe, stable, and efficient operation of gas stations. Whether in the refueling area, oil tank area, or auxiliary facility area of gas stations, SMC manhole covers can exert their safety advantages and become a solid protective shield for gas station operations.